Building Blocks¶

PRISM was created to conduct "full-up" analyses of propulsion systems, however, by its nature it also contains the building blocks to conduct smaller, more focused tasks such as those described below.

Look up Fluid Properties¶

The following script.

#from prism.props.refprop7.n_dll_fluid import n_fluid

from engcoolprop.ec_fluid import EC_Fluid

h = EC_Fluid("N2")

h.setPD( P=50.0, D=0.1)

h.printTPD()

h.setTP(T=400.0, P=500.0)

h.printTPD()

h.constS_newP(P=1000.0)

h.printTPD()

Gives Output:

N2 T=1303.3 P= 50.0 D=0.1000 E=235.32 H=327.91 S=1.771 Q=4.74

N2 T= 400.0 P= 500.0 D=3.4128 E= 66.10 H= 93.23 S=1.299 Q=999.00

N2 T= 491.3 P=1000.0 D=5.4081 E= 80.12 H=114.36 S=1.299 Q=999.00

Look up CEA Isp¶

Bipropellant¶

The following script.

from prism.isp.cea.CEA_Isp import CEA_Isp

Pc=200.0

MR=1.0

eps=10.0

print 'at Pc=%g psia, MR=%g, Area Ratio=%g'%(Pc,MR,eps)

ispObj = CEA_Isp(propName='', oxName='LOX', fuelName="CH4")

IspODE, Cstar, Tcomb = ispObj.get_IvacCstrTc(Pc=Pc, MR=MR, eps=eps )

print 'for propellant =',ispObj.desc

print 'IspODE=%g sec, Cstar=%g ft/sec, Tcomb=%g degR'%(IspODE, Cstar, Tcomb)

Gives Output:

at Pc=200 psia, MR=1, Area Ratio=10

reading cea isp data files for LOX / CH4

for propellant = LOX / CH4

IspODE=246.205 sec, Cstar=4427.22 ft/sec, Tcomb=2076.43 degR

Monopropellant¶

The following script.

from prism.isp.cea.CEA_Isp import CEA_Isp

Pc=200.0

eps=10.0

print 'at Pc=%g psia, Area Ratio=%g'%(Pc,eps)

ispObj = CEA_Isp(propName="HAN315")

IspODE, Cstar, Tcomb = ispObj.get_IvacCstrTc(Pc=Pc, eps=eps )

print 'for propellant =',ispObj.desc

print 'IspODE=%g sec, Cstar=%g ft/sec, Tcomb=%g degR'%(IspODE, Cstar, Tcomb)

Gives Output:

Config File: C:\Users\Charlie\PRISM.cfg

Refprop dll_path = C:/RefProp8/

at Pc=200 psia, Area Ratio=10

reading cea isp data files for HAN315

for propellant = HAN315

IspODE=241.309 sec, Cstar=4499.55 ft/sec, Tcomb=3731.46 degR

Solid Propellant¶

The following script.

from prism.isp.cea.CEA_Isp import CEA_Isp

Pc=200.0

eps=10.0

print 'at Pc=%g psia, Area Ratio=%g'%(Pc,eps)

ispObj = CEA_Isp(propName="ARC448")

IspODE, Cstar, Tcomb = ispObj.get_IvacCstrTc(Pc=Pc, eps=eps )

print 'for propellant =',ispObj.desc

print 'IspODE=%g sec, Cstar=%g ft/sec, Tcomb=%g degR'%(IspODE, Cstar, Tcomb)

Gives Output:

Config File: C:\Users\Charlie\PRISM.cfg

Refprop dll_path = C:/RefProp8/

at Pc=200 psia, Area Ratio=10

reading cea isp data files for ARC448

for propellant = ARC448

IspODE=228.243 sec, Cstar=4290.93 ft/sec, Tcomb=3455.97 degR

Calculate TDK Isp¶

The following script.

from prism.isp.tdk import TDKwrap

tdk = TDKwrap.TDK( oxName='O2', fuelName='CH4',raoNozzle=0, varGammaRao=0,

fracFuelL=None, fracOxL=None,

MR=3.0, eps=150.0, Rthrt=1.0,

Pc=250.0, THETAB=25.0,

RWTU = 1.0, RWTD = 1.0, calcBL=1, IWALL=4, THETAI=30.0, ScarfAng=0.0,

SkewParabTheta=None, SkewParabExitAng=None,

pcentBell=74.0, Pamb=0.0, findOptParab=0, saveFile='ame_nom', useDBruns=1,

inpNozContour=None)

print 'tdk.Isp ', tdk.Isp

print 'tdk.Cstar',tdk.Cstar

print 'tdk.etaKin1D',tdk.etaKin1D

print 'tdk.etaKin2D',tdk.etaKin2D

print 'Pexit=',tdk.Pexit

print

print 'IspTDK_wBL=',tdk.IspTDK_wBL

print 'IspODE=',tdk.IspODE

Gives Output:

tdk.Isp 369.1169

tdk.Cstar 6127.79

tdk.etaKin1D 0.973964333441

tdk.etaKin2D 0.966432474834

Pexit= 0.1008

IspTDK_wBL= 364.932178

IspODE= 381.9376

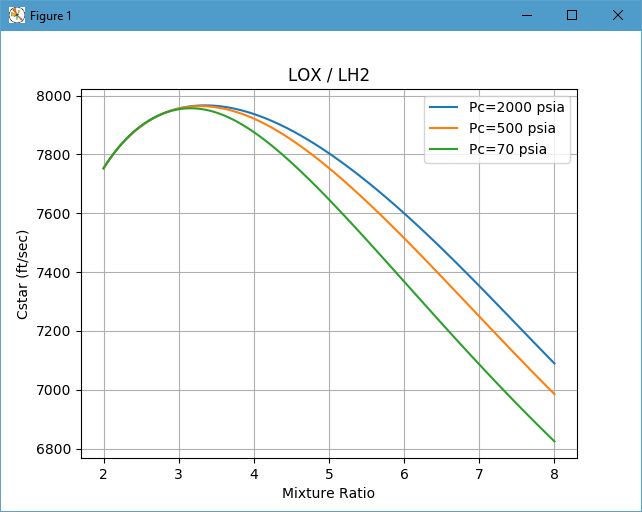

Matplotlib Graph of CEA Output¶

A matplotlib chart of LOX/LH2 CEA data can be created as shown below.

The above chart was created by the following script.

from prism.isp.cea.CEA_Isp import CEA_Isp

from pylab import *

Pc = 500.0

pcL = [ 2000., 500., 70.]

ispObj = CEA_Isp(propName='', oxName='LOX', fuelName="LH2")

for Pc in pcL:

cstarArr = []

MR = 2.0

mrArr = []

while MR < 8.0:

cstarArr.append( ispObj.get_Cstar( Pc=Pc, MR=MR) )

mrArr.append(MR)

MR += 0.05

plot(mrArr, cstarArr, label='Pc=%g psia'%Pc)

legend(loc='best')

grid(True)

title( ispObj.desc )

xlabel( 'Mixture Ratio' )

ylabel( 'Cstar (ft/sec)' )

savefig('cea_cstar_plot.png', dpi=120)

show()

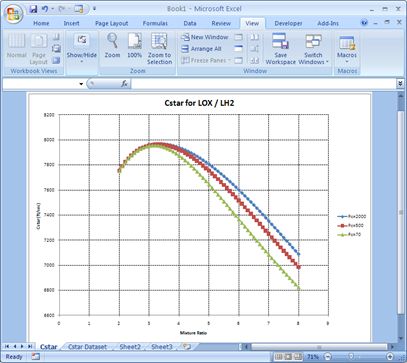

Excel Graph of CEA Output¶

An Excel chart of LOX/LH2 CEA data can be created as shown below.

Cstar¶

The above chart was created by the following script.

from prism.utils import xlChart

from numpy import arange

from prism.isp.cea.CEA_Isp import CEA_Isp

pcL = [ 2000., 500., 70.]

topRow = ['MR']

for Pc in pcL:

topRow.append( 'Pc=%g'%Pc )

rs = [topRow]

ispObj = CEA_Isp(propName='',

oxName='LOX', fuelName="LH2")

mrL = arange(2.0,8.1,0.1)

for MR in mrL:

row = [MR]

for Pc in pcL:

row.append( ispObj.get_Cstar( Pc=Pc, MR=MR) )

rs.append(row)

xl = xlChart.xlChart()

xl.makeChart(rs, title="Cstar for "+ispObj.desc, nCurves = len(pcL),

chartName="Cstar",

sheetName="Cstar Dataset",

yLabel="Cstar (ft/sec)", xLabel="Mixture Ratio")

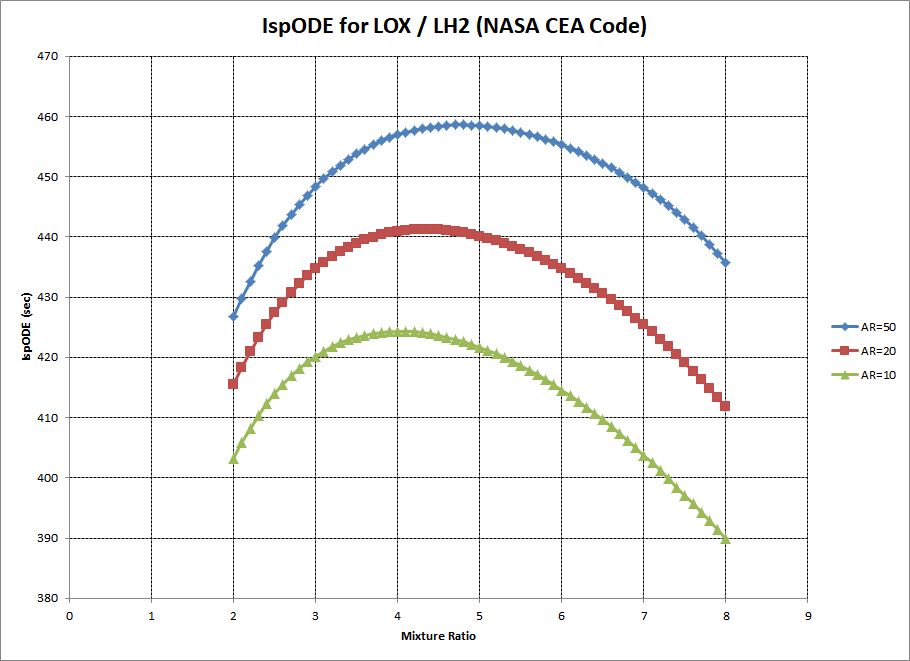

Isp¶

The above chart was created by the following script.

from prism.utils import xlChart

from numpy import arange

from prism.isp.cea.CEA_Isp import CEA_Isp

Pc = 500.0

epsL = [ 50., 20., 10.]

topRow = ['MR']

for eps in epsL:

topRow.append( 'AR=%g'%eps )

rs = [topRow]

ispObj = CEA_Isp(propName='', oxName='LOX', fuelName="LH2")

mrL = arange(2.0,8.1,0.1)

for MR in mrL:

row = [MR]

for eps in epsL:

IspODE, Cstar, Tcomb = ispObj.get_IvacCstrTc(Pc=Pc, MR=MR, eps=eps )

row.append( IspODE )

rs.append(row)

xl = xlChart.xlChart()

xl.makeChart(rs, title="IspODE for "+ispObj.desc+" (NASA CEA Code)", nCurves=len(epsL),

chartName="IspODE",

sheetName="IspODE Dataset",

yLabel="IspODE (sec)", xLabel="Mixture Ratio")

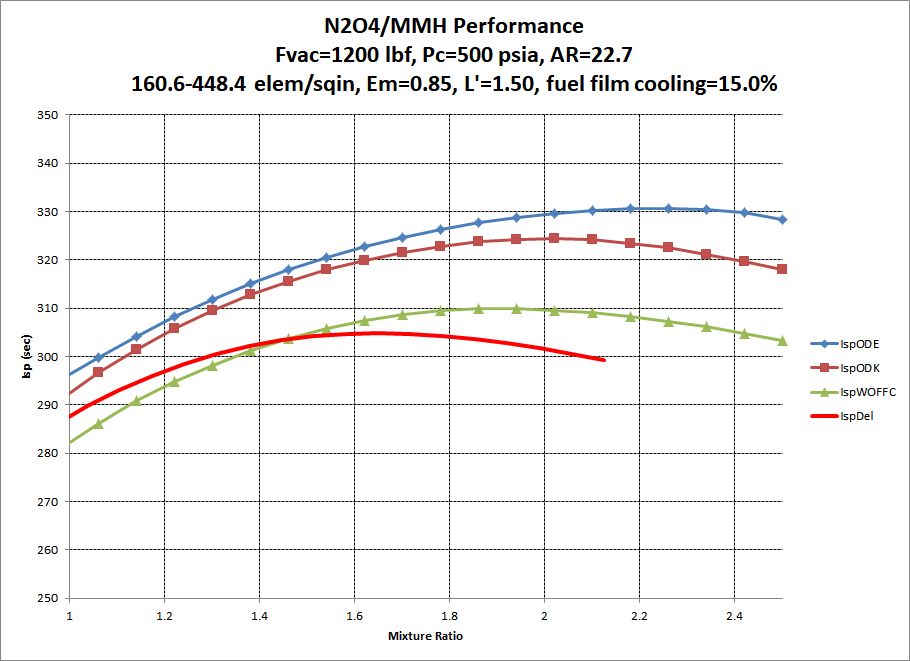

TDK Delivered Isp¶

The above chart was created by the following script.

from prism import *

from prism.utils import xlChart

pcentFFC=15.0

etaPulse=1.0

mrBarrier=0.15

FvacGoal = 1200.0

elemDens=None # if None use d/v

Em=0.85

pc=500.0

eps=22.7

oxName= 'N2O4'

fuelName='MMH'

Tox=500.0 # Tox=None if using reference point

Tfuel=500.0 # Tfuel=None if using reference point

props = oxName + '/' + fuelName

mrLow=0.5

mrHigh=2.5

Nsteps = 25

LoverDt=0.1

LchamMin=1.5

rs = [ ['MRcore','IspODE','IspODK','IspWOFFC','IspDel','MRengine','Tcomb','CstarWOFFC','AreaRatio','Pc',

'etaKin', 'etaDiv', 'etaBL', 'etaVap', 'etaMix', 'etaEm', 'etaFFC', 'etaPulse'] ]

delMR = (mrHigh-mrLow)/Nsteps

LprimeMin = 99999.0

LprimeMax = 0.0

elemDensMin = 99999.0

elemDensMax = 0.0

for i in range(Nsteps+1):

mr = mrLow + i * delMR

Engine = Engine_FFC(name="Est Engine",

oxName=oxName, fuelName=fuelName, etaERE=0.98,

Pc=pc, Fvac=FvacGoal, eps=eps, mr=mr, CR=2.5, LoverDt=LoverDt, LchamMin=LchamMin,

pcentBell=80.0)

if Engine.Lcham > LprimeMax: LprimeMax = Engine.Lcham

if Engine.Lcham < LprimeMin: LprimeMin = Engine.Lcham

LP = Lperf( engine = Engine ,Tox=Tox, Tfuel=Tfuel, elemDens=elemDens,

pcentFFC=pcentFFC, mrBarrier=mrBarrier, etaPulse=etaPulse, Em=Em)

if LP.elemDensCalc > elemDensMax: elemDensMax = LP.elemDensCalc

if LP.elemDensCalc < elemDensMin: elemDensMin = LP.elemDensCalc

IspWOFFC = LP.IspDel / LP.etaFFC

rs.append( [mr, LP.IspODE, LP.IspODK, IspWOFFC, LP.IspDel,LP.mrEngine,

LP.TcombODE, LP.CstarDel, eps, pc,

LP.etaKin, LP.etaDiv, LP.etaBL, LP.etaVap, LP.etaMix, LP.etaEm, LP.etaFFC, LP.etaPulse] )

print Engine.getSummary()

print LP.getSummary()

xl = xlChart.xlChart()

xl.xlApp.DisplayAlerts = 0 # Allow Quick Close without Save Message

#xl.makeDataSheet( _resultsRS, sheetName="Tank Fill")

if '%.2f'%LprimeMin=='%.2f'%LprimeMax:

LprimeStr = "%.2f"%LprimeMin

else:

LprimeStr = "%.2f-%.2f"%(LprimeMin,LprimeMax)

if '%.1f'%elemDensMin=='%.1f'%elemDensMax:

elemDensStr = '%.1f'%elemDensMin

else:

elemDensStr = '%.1f-%.1f'%(elemDensMin,elemDensMax)

if elemDens:

myTitle = "%s Performance\nFvac=%.0f lbf, Pc=%.0f psia, AR=%.1f\n%.2f elem/sqin, Em=%.2f, L'=%s, fuel film cooling=%.1f%%"%\

(props, FvacGoal, pc, eps, elemDens, Em, LprimeStr, pcentFFC)

else:

myTitle = "%s Performance\nFvac=%.0f lbf, Pc=%.0f psia, AR=%.1f\n%s elem/sqin, Em=%.2f, L'=%s, fuel film cooling=%.1f%%"%\

(props, FvacGoal, pc, eps, elemDensStr, Em, LprimeStr, pcentFFC)

xl.makeChart(rs,

title=myTitle,nCurves = 4,

chartName="Performance",

sheetName="FillData",yLabel="Isp (sec)", xLabel="Mixture Ratio")

xl.changeSeriesXValuesColumn( NColumn=6, NSeries=4)

#xl.putSeriesOnSecondary(2, y2Label="Temperature (degR)")

#xl.makeNewChartOfPlottedColumns(cols=(7,), ZeroBased=0, chartName='Quality')

#xl.changePlotTitle( 'Quality of %s'%tf.gasData.name )

#xl.labelPrimaryYAxis( 'Quality of %s (fraction gas)'%tf.gasData.name )

xl.labelXAxis( 'Mixture Ratio' )

xl.setXrange( 1.0, 2.5)

xl.setYrange( 250.0, 350.0)

xl.setLineThickness( NSeries=4, thickness=5)

xl.setSeriesColor( NSeries=4, red=255, green=0, blue=0)

xl.turnMarkerOnOff( NSeries=4, showPoints=0)

Calculate Friction Factor¶

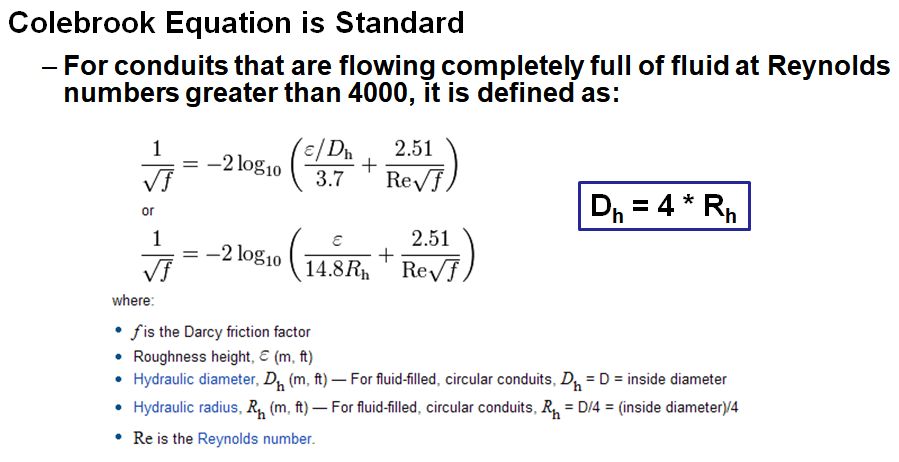

The Colebrook equation is the most standard approach to calculating friction factor.

Because of Colebrook's iterative nature, however, other non-iterative equations are sometimes used:

Haaland Equation is Non-iterative

ffHaaland = (1.0/ (-1.8*log10((eod/3.7)**1.11 + 6.9/ReNum)) )**2

Buzzelli Equation is Non-iterative

From the "Fluid Power" article for single pass evaluation of colebrook

by Dennis Buzzelli June 19, 2008

Transition from Laminar to Turbulent is at Reynolds Numbers from about 2300 to 4000

The following script calculates all three of these approaches.

from prism.utils.colebrook import colebrook_ffact, buzzelli_ffact

from math import log10

ReNum = 2.0E5

diam = 0.2

rough = 0.0001 # in

eod = rough / diam

ffColebrook = colebrook_ffact(rough,diam,ReNum)

ffBuzzelli = buzzelli_ffact(eod, ReNum)

ffHaaland = (1.0/ (-1.8*log10((eod/3.7)**1.11 + 6.9/ReNum)) )**2

print 'Colebrook:','%g'%ffColebrook

print 'Buzzelli :','%g'%ffBuzzelli, \

'(%+.2f'%((ffBuzzelli-ffColebrook)*100.0/ffColebrook),'% Error)'

print 'Haaland :','%g'%ffHaaland, \

'(%+.2f'%((ffHaaland-ffColebrook)*100.0/ffColebrook),'% Error)'

Gives Output:

Colebrook: 0.0188198

Buzzelli : 0.0188215 (+0.01 % Error)

Haaland : 0.0186371 (-0.97 % Error)

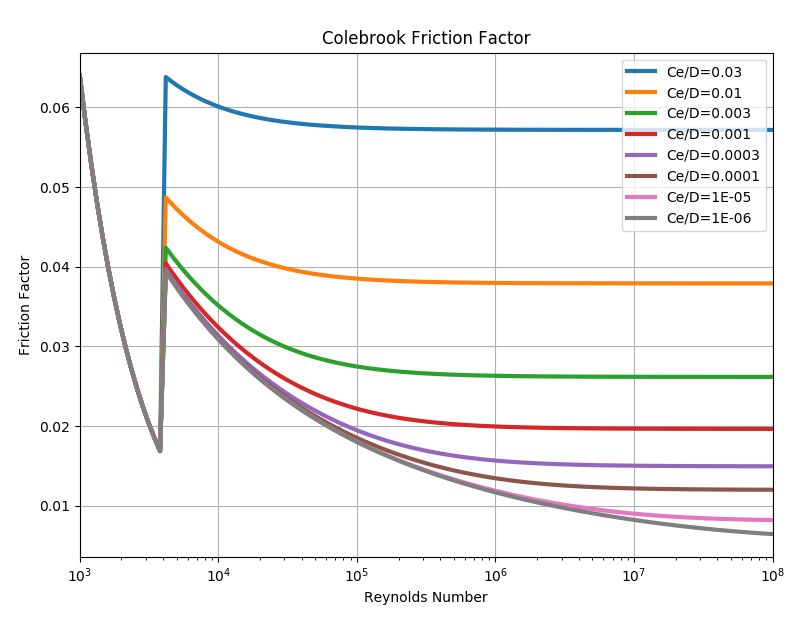

A graph of the Colebrook equation is created by the following script

from pylab import *

from prism.utils.colebrook import colebrook_ffact, buzzelli_ffact

e = 5.0e-6

diam = 1.0

eList = [.03, .01, .003, .001, .0003, .0001, .00001, .000001]

cycle = [1.0]

while cycle[-1]<10.0:

cycle.append( cycle[-1] * 1.1 )

cycle = cycle[:-1]

ReList = [1.E3, 1.E4, 1.E5, 1.E6, 1.E7]

for e in eList:

xRe = []

yFF = []

for ReBase in ReList:

for cyVal in cycle:

ReNum = ReBase * cyVal

ff = colebrook_ffact(e,diam,ReNum)

#print ReNum, ff

xRe.append( ReNum )

yFF.append( ff )

#p.add( biggles.Curve(xRe, yFF, color="red") )

semilogx(xRe,yFF,linewidth=3, label='Ce/D=%G'%e )

legend(loc='best')

grid(True)

title( "Colebrook Friction Factor" )

xlabel( "Reynolds Number" )

ylabel( "Friction Factor" )

ax = axes()

ax.set_xlim( (1.0E3, 1.0E8) )

show()

And gives the output:

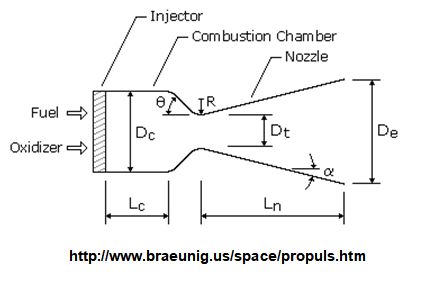

Create a Nozzle Profile¶

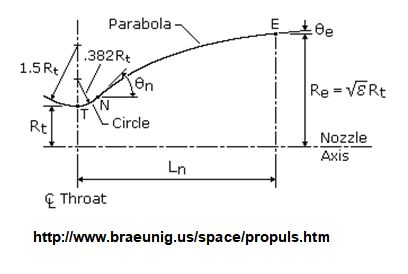

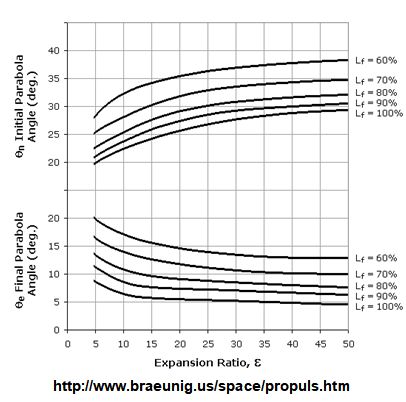

Nozzle contours are generally created as parabolic or Rao. Parabolic contours can be just as high performing as Rao, and may have better mechanical properties. (i.e. the entrance angle to the nozzle tends to be slightly smaller in parabolic than in Rao)

PRISM contains routines to create a parabolic contour and the TDK program has an option to create a Rao nozzle contour.

Parabolic¶

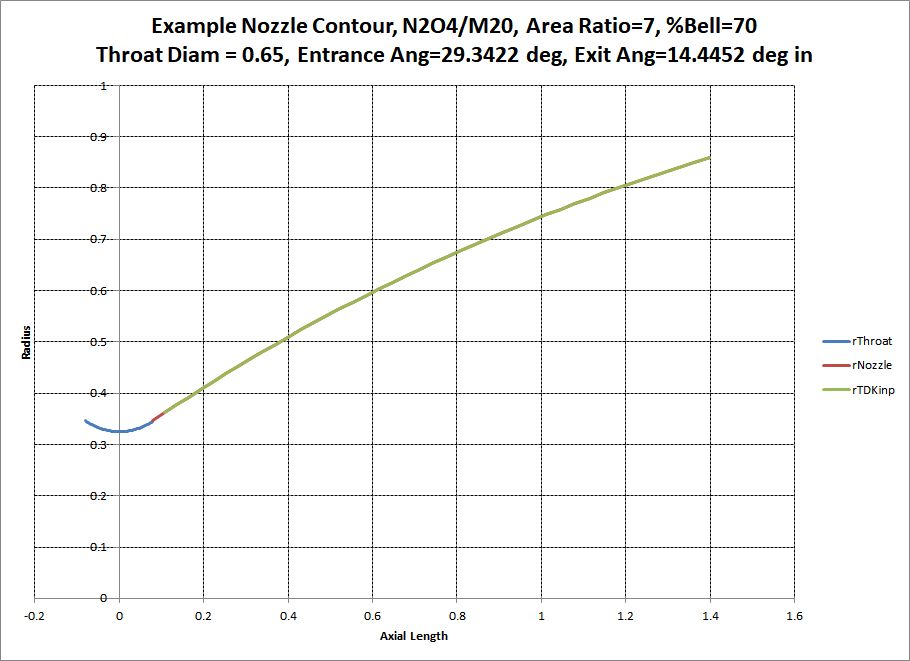

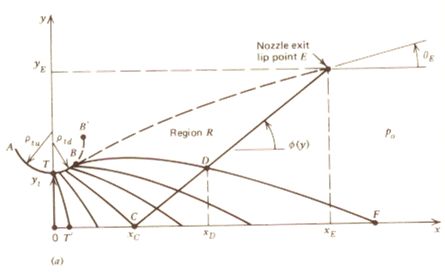

A parabolic contour is defined as shown below. There are general guidelines for choosing the entrance and exit angles of the nozzle as shown in the diagram.

The following script.

from prism.isp.tdk import raoContour, parabolic

from math import *

from prism.isp.cea.CEA_Isp import CEA_Isp

pc=400.0

pcentBell=70.0

eps=7.0

oxName= 'N2O4'

fuelName='M20'

mr = 1.0

Dthrt = 0.65

Rthrt = Dthrt/2.

ispObj = CEA_Isp(oxName=oxName, fuelName=fuelName)

IspODE, Cstar, Tcomb, mw, gam = ispObj.get_IvacCstrTc_ChmMwGam( Pc=pc, MR=mr, eps=eps)

print 'Using gamma =',gam

p = parabolic.Parabola(Rt=Rthrt, eps=eps, pcentBell=pcentBell, gam=gam, Rd=0.5, showPlot=0)

myTitle = "Example Nozzle Contour, %s/%s, Area Ratio=%g, %%Bell=%g\nThroat Diam = %g, Entrance Ang=%g deg, Exit Ang=%g deg in"%\

(oxName, fuelName, eps, pcentBell, Dthrt, p.theta, p.exitAng)

p.makeExcelPlots( title=myTitle, absUnits=1)

Creates an Excel spreadsheet with the following output:

Rao¶

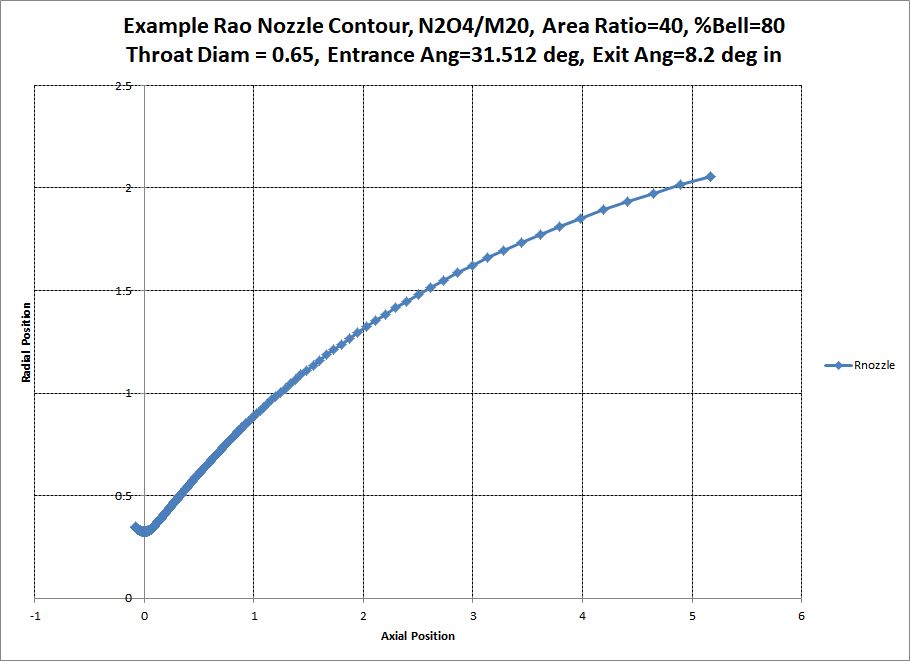

A Rao nozzle is designed by an optimized Method of Characteristics inside the TDK code.

The following script.

from prism.isp.tdk import raoContour, parabolic

from math import *

from prism.isp.cea.CEA_Isp import CEA_Isp

from prism.utils import xlChart

def sinDeg( ang ):

return sin( ang*pi/180.0 )

def cosDeg( ang ):

return cos( ang*pi/180.0 )

def isFloat(s):

'''is the given string a float'''

try: float(s)

except ValueError: return 0

else: return 1

pc=400.0

pcentBell=80.0

eps=40.0

oxName= 'N2O4'

fuelName='M20'

mr = 1.0

Dthrt = 0.65

Rthrt = Dthrt/2.

ispObj = CEA_Isp(oxName=oxName, fuelName=fuelName)

IspODE, Cstar, Tcomb, mw, gam = ispObj.get_IvacCstrTc_ChmMwGam( Pc=pc, MR=mr, eps=eps)

print 'Using gamma =',gam

rao = raoContour.RaoContour2( eps=eps, gam=gam, molWt=mw,

Pc=pc, Tc=Tcomb, THETAB=25.0,

RWTU = 2.0, RWTD = 0.5, RSTAR = 1.0,

pcentBell=pcentBell, Lnoz=0.0, saveFile="testRao",

useRao95=0, odeObj=None, useDBruns=0)

myTitle = "Example Rao Nozzle Contour, %s/%s, Area Ratio=%g, %%Bell=%g\nThroat Diam = %g, Entrance Ang=%g deg, Exit Ang=%g deg in"%\

(oxName, fuelName, eps, pcentBell, Dthrt, rao.entranceAngle, rao.exitAngle )

rs = [ ['x','Rnozzle'] ]

# make the circular arc at the throat

ang = -rao.entranceAngle

while ang<=rao.entranceAngle:

rs.append( [rao.RWTD*sinDeg(ang)*Rthrt, (1.0 + rao.RWTD*(1.-cosDeg(ang)))*Rthrt] )

ang += 1.

rs.append( ['',''] ) # separate circular throat from detailed contour

# add the nozzle

for ZStar,RStar,MachNumber,Theta in rao.contourStar[3:]:

if isFloat(RStar) and isFloat(ZStar):

rs.append( [float(ZStar)*Rthrt, float(RStar)*Rthrt] )

xl = xlChart.xlChart()

xl.xlApp.DisplayAlerts = 0 # Allow Quick Close without Save Message

xl.makeChart(rs, title=myTitle ,nCurves = 1,

chartName="Rao",sheetName="raoData",

yLabel="Radial Position", xLabel="Axial Position")

Creates an Excel spreadsheet with the following output:

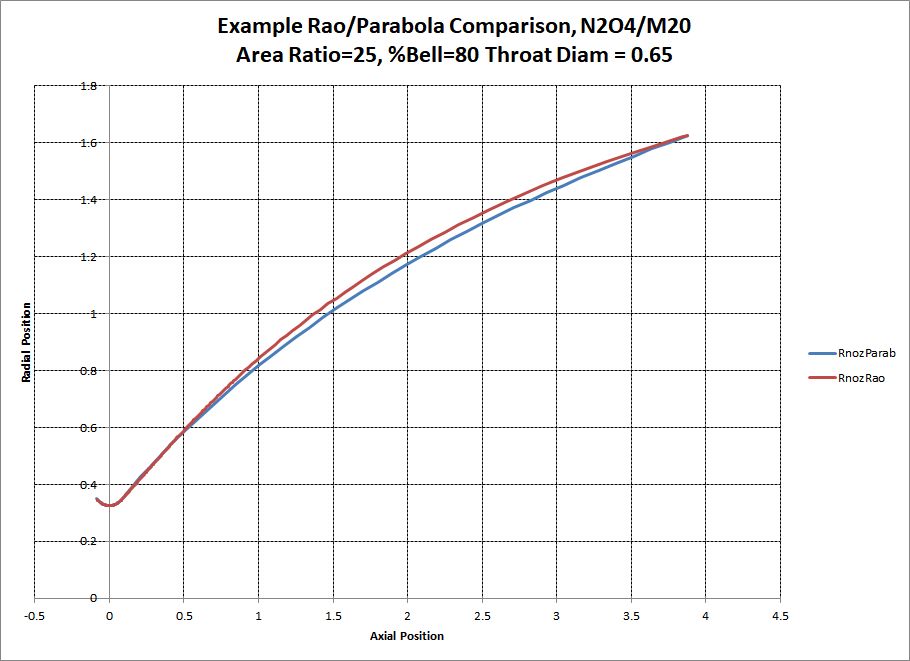

Compare Parabola Rao¶

To compare the two nozzle contours, run the following script.

from prism.isp.tdk import raoContour, parabolic

from math import *

from prism.isp.cea.CEA_Isp import CEA_Isp

from prism.utils import xlChart

def sinDeg( ang ):

return sin( ang*pi/180.0 )

def cosDeg( ang ):

return cos( ang*pi/180.0 )

def isFloat(s):

'''is the given string a float'''

try: float(s)

except ValueError: return 0

else: return 1

pc=400.0

pcentBell=80.0

eps=25.0

oxName= 'N2O4'

fuelName='M20'

mr = 1.0

Dthrt = 0.65

Rthrt = Dthrt/2.

ispObj = CEA_Isp(oxName=oxName, fuelName=fuelName)

IspODE, Cstar, Tcomb, mw, gam = ispObj.get_IvacCstrTc_ChmMwGam( Pc=pc, MR=mr, eps=eps)

print 'Using gamma =',gam

p = parabolic.Parabola(Rt=Rthrt, eps=eps, pcentBell=pcentBell, gam=gam, Rd=0.5, showPlot=0)

rao = raoContour.RaoContour2( eps=eps, gam=gam, molWt=mw,

Pc=pc, Tc=Tcomb, THETAB=25.0,

RWTU = 2.0, RWTD = 0.5, RSTAR = 1.0,

pcentBell=pcentBell, Lnoz=0.0, saveFile="",

useRao95=0, odeObj=None, useDBruns=0)

myTitle = "Example Rao/Parabola Comparison, %s/%s\nArea Ratio=%g, %%Bell=%g Throat Diam = %g"%\

(oxName, fuelName, eps, pcentBell, Dthrt)

rsP = [ ['x','RnozParab'] ]

# make the circular arc at the throat

ang = -p.theta

while ang<=p.theta:

rsP.append( [p.Rd*sinDeg(ang)*Rthrt, (1.0 + p.Rd*(1.-cosDeg(ang)))*Rthrt] )

ang += 1.

rsP.append( ['',''] ) # separate circular throat from parabola

# add the parabola

for i, xval in enumerate( p.zContour ):

row = [xval * Rthrt, p.rContour[i] * Rthrt]

rsP.append(row)

rsR = [ ['x','RnozRao'] ]

# make the circular arc at the throat

ang = -rao.entranceAngle

while ang<=rao.entranceAngle:

rsR.append( [rao.RWTD*sinDeg(ang)*Rthrt, (1.0 + rao.RWTD*(1.-cosDeg(ang)))*Rthrt] )

ang += 1.

rsR.append( ['',''] ) # separate circular throat from detailed contour

# add the nozzle

for ZStar,RStar,MachNumber,Theta in rao.contourStar[3:]:

if isFloat(RStar) and isFloat(ZStar):

rsR.append( [float(ZStar)*Rthrt, float(RStar)*Rthrt] )

rs = xlChart.combineRS( rsP, rsR )

xl = xlChart.xlChart()

xl.xlApp.DisplayAlerts = 0 # Allow Quick Close without Save Message

xl.makeChart(rs, myTitle ,nCurves = 1,

chartName="RaoParab",sheetName="raoParabData",

yLabel="Radial Position", xLabel="Axial Position")

xl.addNewSeriesToCurrentSheetChart( xColumn=3, yColumn=4)

xl.turnMarkersOnOff( showPoints=0)

Creates an Excel spreadsheet that compares the two contours:

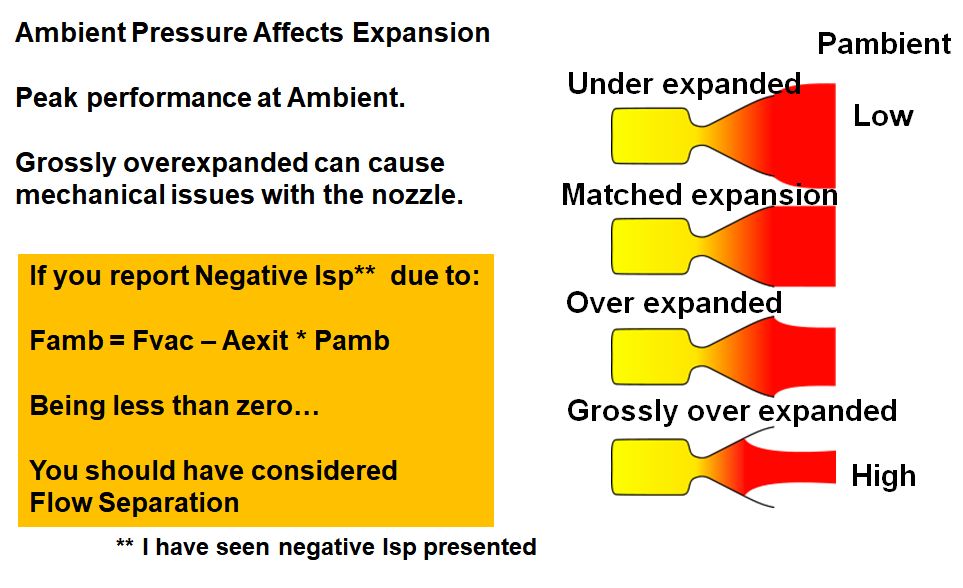

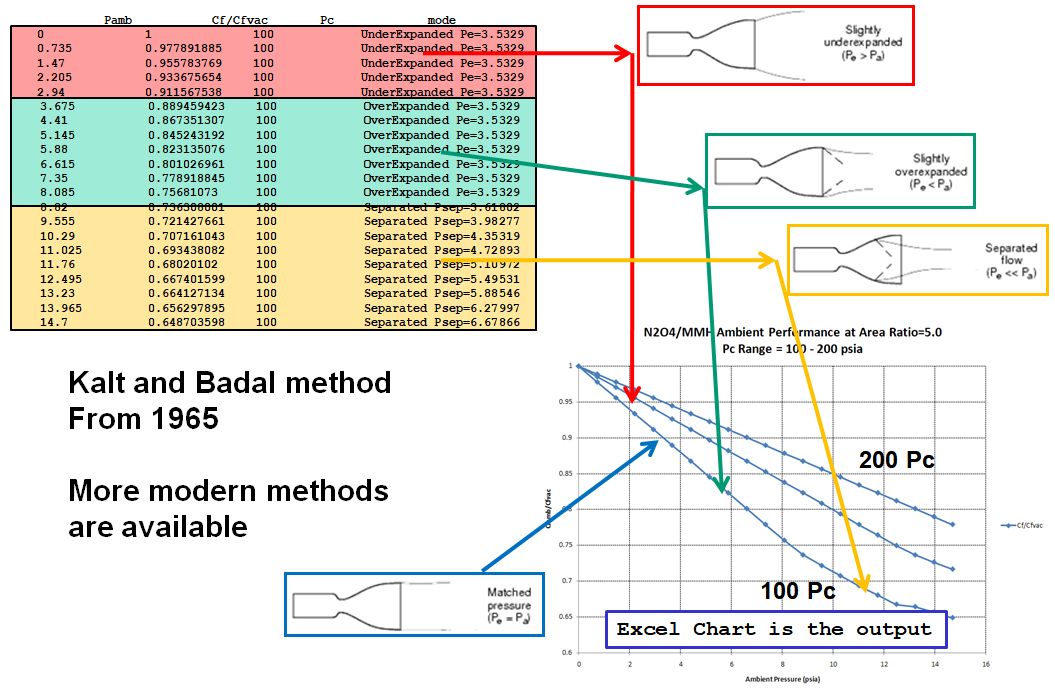

Nozzle Flow Separation¶

The following script runs nozzle separation calculations.

from prism.isp import separated_Cf

from prism.utils import xlChart

from prism.isp.cea.CEA_Isp import CEA_Isp

Fvac = 110.0

pc=108.0

eps=5.0

oxName= 'N2O4'

fuelName='MMH'

mr = 1.65

Nsteps = 20

ispObj = CEA_Isp(oxName=oxName, fuelName=fuelName)

IspODE, Cstar, Tcomb, mw, gam = ispObj.get_IvacCstrTc_ChmMwGam( Pc=pc, MR=mr, eps=eps)

print 'Using gamma =',gam

pcArr = [100.0, 150.0, 200.0]

rs = [ [ 'Pamb','Cf/Cfvac', 'Pc','mode'] ]

for pc in pcArr:

for i in range( Nsteps+1):

Pamb = 14.7 * i / Nsteps

Cf, CfOverCfvac, mode = separated_Cf.ambientCf(gam=gam, epsTot=eps, Pc=pc, Pamb=Pamb)

rs.append( [ Pamb, CfOverCfvac, pc, mode] )

rs.append(['','','',''])

xl = xlChart.xlChart()

xl.xlApp.DisplayAlerts = 0 # Allow Quick Close without Save Message

myTitle = "%s/%s Ambient Performance at Area Ratio=%.1f\n"%(oxName, fuelName, eps) +\

"Pc Range = %g - %g psia"%(min(pcArr), max(pcArr))

xl.makeChart(rs,

title=myTitle,nCurves = 1,

chartName="Performance",

sheetName="FillData",yLabel="Cfamb/Cfvac", xLabel="Ambient Pressure (psia)")

xl.setYrange( 0.6, 1.0)

The script creates an Excel spreadsheet of nozzle separation calculations. A table of nozzle conditions is shown in the upper left corner of the image below. A graph of ambient pressure vs nozzle Cf ambient divided by Cf vacuum is shown in the bottom right corner of the image below:

Solve Nozzle Exit Diameter¶

The following script.

from prism import Goal

from prism import Engine_FFC

EngineDivert = Engine_FFC(name="Divert Engine",

oxName='N2O4', fuelName='MMH', Number=4,

cxw=1.0, Pc=200.0, Fvac=1000.0, eps=10.0, mr=1.65,

CR=2.5, LoverDt=2.0, LchamMin=1.5, cxwValves=1.0,

etaERE=0.97, calcEtaNoz=1, useFastCEALookup=1,isBell=1, pcentBell=80.,

halfAngDeg=15.0, xlnOverLcham=0.9)

print 'Find Area Ratio that has Exit Diameter = 5.0 inches'

print

print 'Initial AR =',EngineDivert.eps,' Dexit =',EngineDivert.Dexit

def newDexit( e ):

EngineDivert.eps = e

EngineDivert.reCalc()

return EngineDivert.Dexit

G = Goal(goalVal=5.0, minX=2.0, maxX=80.0,

funcOfX=newDexit, tolerance=1.0E-5, maxLoops=40, failValue=80.0)

eps, ierror = G()

print

print 'Area Ratio =',eps,'for Dexit =',EngineDivert.Dexit

print EngineDivert.getSummary()

Gives Output:

Find Area Ratio that has Exit Diameter = 5.0 inches

Initial AR = 10.0 Dexit = 6.1915743957

Area Ratio = 6.30835836802 for Dexit = 5.00000001086

Bipropellant Engine: Divert Engine

mass = 49.792 lbm

type = inert

Propellants : N2O4 / MMH

NASA CEA Code for ODE performance

Physical Weight Model

Injector Material is SS

Nozzle Material is Cb103

Bell Nozzle with Percent Bell = 80

Mass is for 4 engines total

==== INPUT ====

Fvac = 1000 lbf

Pc = 200.0 psia

eps = 6.30836

%Bell = 80.00 %

mr = 1.65

CR = 2.5

xlnOverLcham = 0.9

LoverDt = 2

LchamMin = 1.500 in

cxwInj = 1

cxwValves = 1

cxw = 1

etaERE = 0.97

==== OUTPUT ====

Isp = 276.997 sec

Cstar = 5547.8 ft/sec

etaBL = 0.991001

etaDiv = 0.983664

etaKin = 0.984052

etaNoz = 0.959266

effIsp = 0.930488

IspODE = 297.69 sec

CstarODE = 5719.4 ft/sec

Tc = 5544.0 degR

PcFace = 209.609 psia

Pexit = 4.44532 psia

wdotTot = 3.61015 lbm/sec

wdotOx = 2.24783 lbm/sec

wdotFl = 1.36232 lbm/sec

rhoFl = 0.0316 lbm/cuin

rhoOx = 0.0521 lbm/cuin

volDotOx = 43.1645 cuin/sec

volDotFl = 43.1597 cuin/sec

DFlow = 1.353 in

At = 3.11253 sqin

Dt = 1.991 in

Dcham = 3.148 in

Dexit = 5.000 in

Lcham = 3.981 in

xlc = 0.398 in

xln = 3.583 in

Lnoz = 4.492 in

Lengine = 11.621 in

rhoInj = 0.280 lbm/cuin

rhoNoz = 0.310 lbm/cuin

thkCham = 0.026 in

thkNoz = 0.021 in

WtNoz = 0.778 lbm

WtChamber = 0.262 lbm

WtInj = 3.954 lbm

WtAcoustic = 2.804 lbm

WtValves(2) = 4.292 lbm

WtMisc = 0.357 lbm

wt/Engine = 12.448 lbm

F/W = 80.334 lbf/lbm

Solenoid Valve: biprop valves

mass = 4.292 lbm

type = inert

Based on Solenoid Valve Experience

Mass is for 2 valves total

==== INPUT ====

cuInchPerSec = 43.1645 cuin/sec

cxw = 1.000

==== OUTPUT ====

basemass = 2.146 lbm

Size a Liquid Engine¶

The following script.

from prism import Engine_FFC

EngineDivert = Engine_FFC(name="Divert Engine",

oxName='N2O4', fuelName='MMH', Number=4,

cxw=1.0, Pc=200.0, Fvac=1000.0, eps=10.0, mr=1.65,

CR=2.5, LoverDt=2.0, LchamMin=1.5, cxwValves=1.0,

etaERE=0.97, calcEtaNoz=1, useFastCEALookup=1,isBell=1, pcentBell=80.,

halfAngDeg=15.0, xlnOverLcham=0.9)

print EngineDivert.getSummary()

Gives Output:

Bipropellant Engine: Divert Engine

mass = 49.186 lbm

type = inert

Propellants : N2O4 / MMH

NASA CEA Code for ODE performance

Physical Weight Model

Injector Material is SS

Nozzle Material is Cb103

Bell Nozzle with Percent Bell = 80

Mass is for 4 engines total

==== INPUT ====

Fvac = 1000 lbf

Pc = 200.0 psia

eps = 10

%Bell = 80.00 %

mr = 1.65

CR = 2.5

xlnOverLcham = 0.9

LoverDt = 2

LchamMin = 1.500 in

cxwInj = 1

cxwValves = 1

cxw = 1

etaERE = 0.97

==== OUTPUT ====

Isp = 286.35 sec

Cstar = 5547.8 ft/sec

etaBL = 0.988751

etaDiv = 0.987664

etaKin = 0.980909

etaNoz = 0.95791

effIsp = 0.929173

IspODE = 308.177 sec

CstarODE = 5719.4 ft/sec

Tc = 5544.0 degR

PcFace = 209.609 psia

Pexit = 2.34259 psia

wdotTot = 3.49224 lbm/sec

wdotOx = 2.17441 lbm/sec

wdotFl = 1.31782 lbm/sec

rhoFl = 0.0316 lbm/cuin

rhoOx = 0.0521 lbm/cuin

volDotOx = 41.7547 cuin/sec

volDotFl = 41.75 cuin/sec

DFlow = 1.331 in

At = 3.01087 sqin

Dt = 1.958 in

Dcham = 3.096 in

Dexit = 6.192 in

Lcham = 3.916 in

xlc = 0.392 in

xln = 3.524 in

Lnoz = 6.320 in

Lengine = 13.332 in

rhoInj = 0.280 lbm/cuin

rhoNoz = 0.310 lbm/cuin

thkCham = 0.025 in

thkNoz = 0.021 in

WtNoz = 0.958 lbm

WtChamber = 0.249 lbm

WtInj = 3.825 lbm

WtAcoustic = 2.699 lbm

WtValves(2) = 4.220 lbm

WtMisc = 0.346 lbm

wt/Engine = 12.296 lbm

F/W = 81.325 lbf/lbm

Solenoid Valve: biprop valves

mass = 4.220 lbm

type = inert

Based on Solenoid Valve Experience

Mass is for 2 valves total

==== INPUT ====

cuInchPerSec = 41.7547 cuin/sec

cxw = 1.000

==== OUTPUT ====

basemass = 2.110 lbm

To create an image of an engine like below.

use the following script.

from prism.engines.Engine_FFC import Engine_FFC

from prism.pov.POV_Scene import POV_Scene

EngineDivert = Engine_FFC(name="Divert Engine",

oxName='N2O4', fuelName='MMH', Number=4,

cxw=1.0, Pc=200.0, Fvac=1000.0, eps=10.0, mr=1.65,

CR=2.5, LoverDt=2.0, LchamMin=1.5, cxwValves=1.0,

etaERE=0.97, calcEtaNoz=1, useFastCEALookup=1,isBell=1, pcentBell=80.,

halfAngDeg=15.0, xlnOverLcham=0.9)

scene = POV_Scene(ambient=0.3)

scene.addItem( EngineDivert.getPOV_Item() )

scene.write(view="", ortho=1, clockX=-15., clockY=-15.)

scene.render()

Size a Tank¶

The following script.

from prism.tanks.Tank import Tank

oxekv = Tank(name="Divert Vehicle Propellant Tank",

makeCompositeTank=1, kalmod=0,

matlName="grEpox", vfree=486.0,ell=1.767,rcyltd=1.445,

ptank=1400.0,sf=1.5,cxw=1.5,

ithcyl=1,kacqui=1,inpex=1,expefi=0.98,

tblad=0.030,tbond=0.030,ttrspc=0.010,

rhobnd=0.04,rhoacq=0.098,tliner=0.03,rholiner=0.098)

print oxekv.getSummary()

Gives Output:

Cylindrical/Spherical/Elliptical Tank: Divert Vehicle Propellant Tank

mass = 3.763 lbm

type = inert

Composite Tank Algorithm

Bladder Thickness is input at 0.030 in

kalmod = 0

==== INPUT ====

vfree = 486 cuin

vfreeTotal = 486 cuin

ell = 1.767

rcyltd = 1.445

ptank = 1400 psia

sf = 1.5

cxw = 1.5

ithcyl = 1

kacqui = 1 transverse collapsing Alum. bladder

inpex = 1

expefi = 0.98

tblad = 0.030 in

tbond = 0.030 in

ttrspc = 0.010 in

rhobnd = 0.04 lbm/cuin

rhoacq = 0.098 lbm/cuin

tliner = 0.030 in

rholiner = 0.098 lbm/cuin

==== OUTPUT ====

rinsid = 3.535 in

dinsid = 7.069 in

OR = 3.618 in

OD = 7.237 in

OH = 14.385 in

hinsid = 14.215 in

SAinsid = 341.045 sqin

cyl = 10.215 in

wacqui = 0.987 lbm

vacqui = 9.87014 cuin

dpacq = 65.9344 psig

pullag = 1465.93 psia

vresid = 9.72 cuin

vtank = 505.59 cuin

tming = 0.008 in

thkcyl = 0.024 in

thkend = 0.025 in

thkBladOut = 0.030 in

wliner = 1.053 lbm

wtank(+liner) = 1.522 lbm

rho = 0.0637 lbm/cuin

PmeopVoverW = 188096 lbf-in/lbm

Pburst(est.) = 2100.0 psia

PburstVoverW = 282143 lbf-in/lbm

Size a Liquid Line¶

Input Diameter¶

The following script.

from prism import Line_Liq_inpD, Inc_liquid

Fl = Inc_liquid( symbol="N2H4",T=530.0,P=240.0, mass_lbm=10.0)

h = Line_Liq_inpD(name="Fuel Line",wdot=2.0, matlName="Ti", OD=0.5,

liqObj=Fl, Number=10, Kfactors=5.0, pLine=400.0, thkWall=0.045)

print h.getSummary()

Gives Output:

Liquid Line: Fuel Line

mass = 6.432 lbm

type = inert

fluid : N2H4

Structural Material : Ti

Mass is for 10 lines total

==== INPUT ====

wdot = 2 lbm/sec

OD = 0.500 in

thkWall = 0.045 in

len_inches = 50 in

Kfactors = 5 vel heads

roughness = 5e-06 in

pLine = 400 psia

cxw = 1.25

# Lines = 10

==== OUTPUT ====

dpLine = 58.05 psid

dPperVelHead = 8.15 psid

velFPS = 34.6998 ft/sec

ReNum = 1.214732E+05

rinsid = 0.205 in

dinsid = 0.410 in

volLine = 6.60127 cuin

rho = 0.16 lbm/cuin

sy = 119000 psi

sf = 65.3049

tming = 0.030 in

fluid rho = 0.0363801 lbm/cuin

fluid visc = 61.356 1.0E5 * lb/ft-sec

wt/Line = 0.643 lbm

Input Velocity¶

The following script.

from prism import Line_Liq, Inc_liquid

Fl = Inc_liquid( symbol="N2H4",T=530.0,P=240.0, mass_lbm=10.0)

h = Line_Liq(name="Fuel Line",wdot=2.0, matlName="Ti", velFPS=40.0,

liqObj=Fl, Number=10, Kfactors=5.0, pLine=400.0)

print h.getSummary()

Gives Output:

Liquid Line: Fuel Line

mass = 3.882 lbm

type = inert

fluid : N2H4

Structural Material : Ti

Allow Non-Standard wall thickness

Mass is for 10 lines total

==== INPUT ====

wdot = 2 lbm/sec

velFPS = 40 ft/sec

len_inches = 50 in

Kfactors = 5 vel heads

roughness = 5e-06 in

thkInp = 0 in

pLine = 400 psia

sf = 4

cxw = 1.25

# Lines = 10

==== OUTPUT ====

dpLine = 78.53 psig

ReNum = 1.304208E+05

thkLine = 0.030 in

rinsid = 0.191 in

dinsid = 0.382 in

doutside = 0.442 in

volLine = 5.72658 cuin

rho = 0.16 lbm/cuin

sy = 119000 psi

tming = 0.030 in

fluid rho = 0.0363801 lbm/cuin

fluid visc = 61.356 1.0E5 * lb/ft-sec

wt/Line = 0.388 lbm

Size a Gas Line¶

Input Diameter¶

The following script.

from prism import Line_Gas

h = Line_Gas(name="Ox Line",wdot=1.0, matlName="Ti", thkWallInp=0.083,

calcVelFromDiamInp=1, DiamInp=1.0,

usePinlet=1, velFPS=20.0, PgasInlet=1000.0, TgasDegR=530.0,

gasSymbol='O2', Number=10, Kfactors=2.0)

print h.getSummary()

Gives Output:

Gas Line: Ox Line

mass = 23.911 lbm

type = inert

In: O2 T= 530.0 P=1000.0 D=5.8605 E= 76.25 H=107.85 S=1.255 Supercrit

Out:O2 T= 529.9 P= 996.6 D=5.8410 E= 76.25 H=107.85 S=1.256 Supercrit

fluid : O2

Structural Material : Ti

Allow Non-Standard wall thickness

Using Pinlet to design line

Line Diameter is an Input (vel is output)

Mass is for 10 lines total

==== INPUT ====

wdot = 1 lbm/sec

DiamInp = 1.000 in

thkWallInp = 0.083 in

len_inches = 50 in

Kfactors = 2 vel heads

roughness = 5e-06 in

PgasInlet = 1000.0 psia

sf = 4

cxw = 1.25

# Lines = 10

==== OUTPUT ====

PgasOutlet = 996.6 psia

velFPS = 45.139 ft/sec

velHead = 1.289 psi

dpLine = 3.45 psig

dp due to Line = 0.89 psig

dp due to Ks = 2.56 psig

dp/Pinlet = 0.00344998

ReNum = 1.243308E+06

fricfact = 0.0116279

thkLine = 0.083 in

rinsid = 0.417 in

dinsid = 0.834 in

volLine = 27.3144 cuin

rho = 0.16 lbm/cuin

sy = 119000 psi

tming = 0.035 in

fluid dens = 5.86053 lbm/cuft

fluid visc = 1.47634e-05 lb/ft-sec

fluid sonicV = 1085.38 ft/sec

fluid Mach = 0.0415883

wt/Line = 2.391 lbm

Input Velocity¶

The following script.

from prism import Line_Gas

h = Line_Gas(name="Ox Line",wdot=1.0, matlName="Ti", thkWallInp=0.083,

calcVelFromDiamInp=0, DiamInp=1.0,

usePinlet=1, velFPS=100.0, PgasInlet=1000.0, TgasDegR=530.0,

gasSymbol='O2', Number=10, Kfactors=2.0)

print h.getSummary()

Gives Output:

Gas Line: Ox Line

mass = 16.892 lbm

type = inert

In: O2 T= 530.0 P=1000.0 D=5.8605 E= 76.25 H=107.85 S=1.255 Supercrit

Out:O2 T= 529.5 P= 981.9 D=5.7577 E= 76.27 H=107.85 S=1.257 Supercrit

fluid : O2

Structural Material : Ti

Allow Non-Standard wall thickness

Using Pinlet to design line

Line Velocity is an Input (diam is output)

Mass is for 10 lines total

==== INPUT ====

wdot = 1 lbm/sec

velFPS = 100 ft/sec

thkWallInp = 0.083 in

len_inches = 50 in

Kfactors = 2 vel heads

roughness = 5e-06 in

PgasInlet = 1000.0 psia

sf = 4

cxw = 1.25

# Lines = 10

==== OUTPUT ====

PgasOutlet = 981.9 psia

velHead = 6.325 psi

dpLine = 18.15 psig

dp due to Line = 5.89 psig

dp due to Ks = 12.26 psig

dp/Pinlet = 0.0181458

ReNum = 1.851863E+06

fricfact = 0.0108525

thkLine = 0.083 in

rinsid = 0.282 in

dinsid = 0.565 in

volLine = 12.5281 cuin

rho = 0.16 lbm/cuin

sy = 119000 psi

tming = 0.035 in

fluid dens = 5.86053 lbm/cuft

fluid visc = 1.47634e-05 lb/ft-sec

fluid sonicV = 1085.38 ft/sec

fluid Mach = 0.0921338

wt/Line = 1.689 lbm

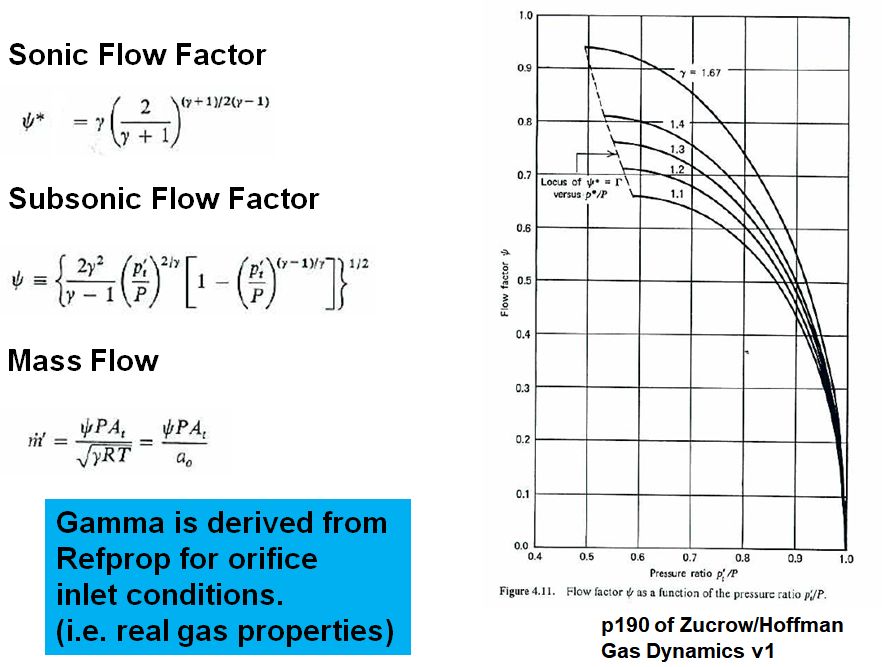

Size a Gas Orifice¶

Gas orifices are sized using the equations below.

An example script to calculate a gas orifice size is:

from prism import Gas_Orifice

orf = Gas_Orifice(name="gas orifice", gasSymbol='O2', matlName="Ti",

CdAInp=0.1, wdot=1.1, TgasDegR=530.0,

usePinlet=0, PgasOutlet=400.0, PgasInlet=400.0,

Number=1, sf=4.0, cxw=1.25)

print orf.getSummary()

and give the following output:

Gives Output:

Gas Orifice: gas orifice

mass = 0.003 lbm

type = inert

In: O2 T= 530.0 P= 521.3 D=3.0013 E= 79.18 H=111.34 S=1.301 Supercrit

Out:O2 T= 526.1 P= 400.0 D=2.3098 E= 79.28 H=111.34 S=1.317 Supercrit

fluid : O2

Structural Material : Ti

Allow Non-Standard wall thickness

Using Poutlet to design Orifice

Orifice CdA is an Input

Orifice is SUB-SONIC

==== INPUT ====

wdot = 1.1 lbm/sec

SCFM = 797.491 SCFM

CdAInp = 0.1 in

PgasOutlet = 400.0 psia

sf = 4

cxw = 1.25

# Orifices = 1

==== OUTPUT ====

PgasInlet = 521.3 psia

velFPS = 527.77 ft/sec

dpOrifice = 121.32 psid

dp/Pinlet = 0.232717

thkWall = 0.030 in

rinsid = 0.178 in

dinsid = 0.357 in

rho = 0.16 lbm/cuin

sy = 119000 psi

tming = 0.030 in

fluid dens = 3.00131 lbm/cuft

fluid visc = 1.41988e-05 lb/ft-sec

fluid sonicV = 1075.42 ft/sec

fluid Mach = 0.490757

Size a Gas Regulator¶

Similar methods as above are used to size a gas regulator:

from prism import Gas_Regulator

reg = Gas_Regulator(name="gas regulator", gasSymbol='O2', matlName="Ti",

wdot=1.0, TgasInit=530.0, TgasFinal=400.0,

PgasOutlet=400.0, PgasInit=4000.0, PgasFinal=800.0,

Number=1, CdASF=1.5, sf=4.0, cxw=1.25)

print reg.getSummary()

Gives Output:

Gas Regulator: gas regulator

mass = 0.244 lbm

type = inert

Initial:

In: O2 T= 530.0 P=4000.0 D=23.2378 E= 59.45 H= 91.32 S=1.143 Supercrit

Out:O2 T= 440.1 P= 400.0 D=2.8238 E= 65.09 H= 91.32 S=1.276 Supercrit

Final:

In: O2 T= 400.0 P= 800.0 D=6.7375 E= 54.27 H= 76.26 S=1.200 Supercrit

Out:O2 T= 377.7 P= 400.0 D=3.4004 E= 54.48 H= 76.26 S=1.239 Supercrit

fluid : O2

Structural Material : Ti

Allow Non-Standard wall thickness

Final condition is SUB-SONIC

==== INPUT ====

wdot = 1 lbm/sec

SCFM = 724.992 SCFM

TgasInit = 530.0 degR

PgasInit = 4000.0 psia

TgasFinal = 400.0 degR

PgasFinal = 800.0 psia

PgasOutlet = 400.0 psia

CdASF = 1.5

sf = 4

cxw = 1.25

# Regs = 1

==== OUTPUT ====

CdAInit = 0.0094 sqin

CdAFinal = 0.0421 sqin

CdA = 0.0631 sqin

dpRegulator = 400.00 psig

dp/Pinlet = 0.5

rinsid = 0.142 in

dinsid = 0.284 in

rho = 0.16 lbm/cuin

sy = 119000 psi

tming = 0.030 in

fluid dens = 23.2378 lbm/cuft

fluid visc = 2.08782e-05 lb/ft-sec

fluid sonicV = 1317.98 ft/sec

Helium Pressurization¶

The sizing of a Helium pressurization system depends on:

- Helium MEOP

- Propellant Tank Pressure

- Propellant Tank Volume

- Helium ACS Requirements

- Operating Temperature Range

- Mission Time

- Regulator Delta P Requirements

- Average Acceleration

- Tankage Mass, Surface Area, Material

- External Heat Loads

Create Summary¶

The following script takes these into consideration.

from prism import PressurantInteg

h = PressurantInteg(name="General Test", gas='HE',

VpropTnk=300000.0,PGasTnkMEOP=4455.0,PpropNom=180.0,

Nbottle=4,

PfinGasOvPnom=0.9, heatExchangerTout=None,

tAction=400.0,TminR=510.0,TmaxR=550.0, useDBruns=0, TbottleMatlConst=None)

print h.getSummary()

Gives Output:

Helium Pressurant: General Test

mass = 24.742 lbm

type = pressurant

Integrated Heat Transfer

==== INPUT ====

VpropTnk = 300000 cuin

PGasTnkMEOP = 4455 psia

PpropNom = 180 psia

PfinGasOvPnom = 0.9

tAction = 400 sec

TminR = 510.0 degR

TmaxR = 550.0 degR

==== OUTPUT ====

WGasTotal = 24.742 lbm

WtGasResid = 1.667 lbm

WGasNon-Resid = 23.075 lbm

Vbottle = 16117 cuin

wdotGas = 0.0576869 lbm/sec

compressInit = 1.1403

PbottleCold = 4135.27 psia

densInitBot = 2.65275 lbm/cuft

densFinalBot = 0.178768 lbm/cuft

densFinalProp = 0.138971 lbm/cuft

gammaIsen = 1.63927

gamPolyBottle = 1.14896

gamPolyTank = 1.01908

fracIsenBottle = 0.233009

fracIsenTank = 0.0298427

TfinalPropGas = 480.0 degR

TfinalGasBot = 335.1 degR

PfinalGasBot = 162.0 psia

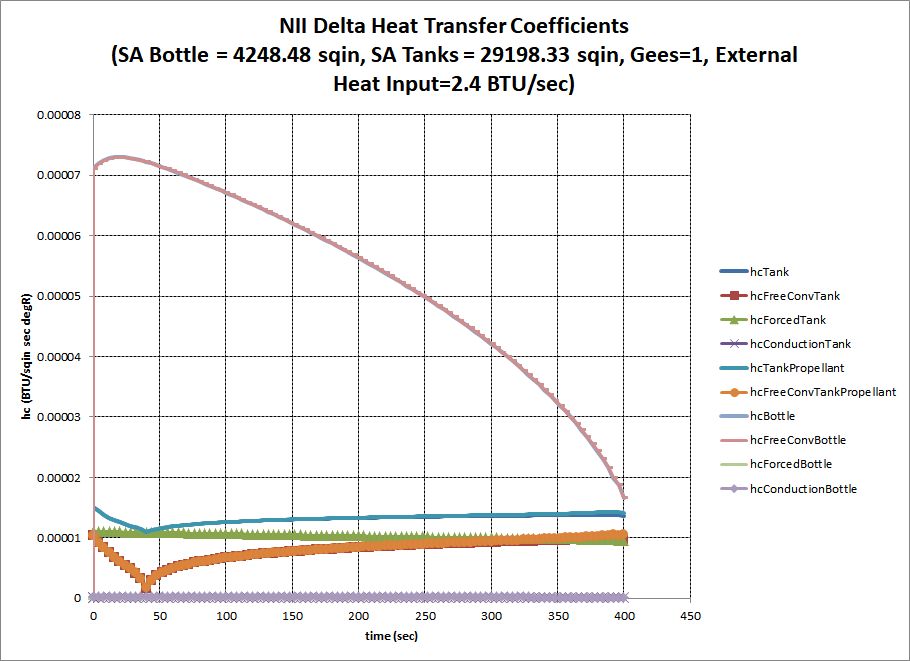

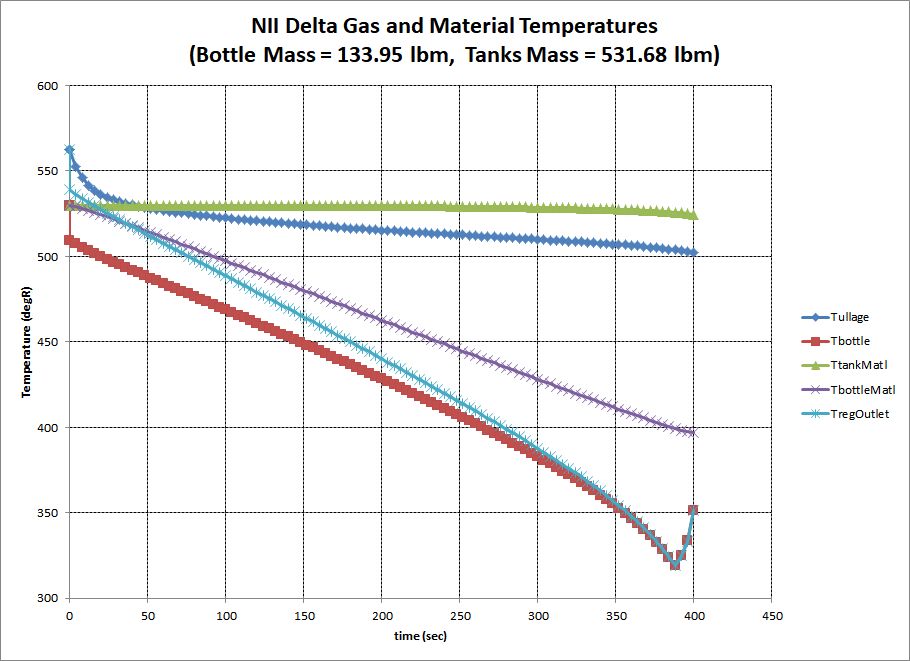

Show Calculation Details¶

from prism import TankPress

# simulation of NII Delta He pressurization

Vfull = 5.69 * 1728.0

Voull = 5.0 * 1728.0

Vftank = 78.66 * 1728.0

Votank = 95.11 * 1728.0

Vtanks = Vftank + Votank

Vullage = Vfull + Voull

Vliq = Vtanks - Vullage

tburn = 400.0

Vbottle = 8.7 * 1728.0

Pbottle=4455.0

Peff = (Vftank*184.4 + Votank*171.0)/Vtanks

tf = TankPress(gas="HE", Vbottle=Vbottle, Vullage=Vullage, Vliq=Vliq, vdotLiq=Vliq/tburn,

Pbottle=Pbottle, Ptank=Peff,

Tbottle=530.0, Tullage=530.0, initTullage=1, AccGees=1.0,

PVoW_Bottle=500000., PVoW_Tank=100000.,

Nbottle=3, ellBottle=1.0, LcylOvDBottle=0.0, Cp_effBottle=0.125, # Cp Ti=.125, Al=.2, Monel=.1

Ntank=2, ellTank=1.414, LcylOvDTank=1.0, Cp_effTank=0.15,

CdARegMax=None, NtimeSteps=100,

QexternalIntoBottle=2.4, dPregulator=2.0 )

tf.makeExcelPlots( title='NII Delta' )

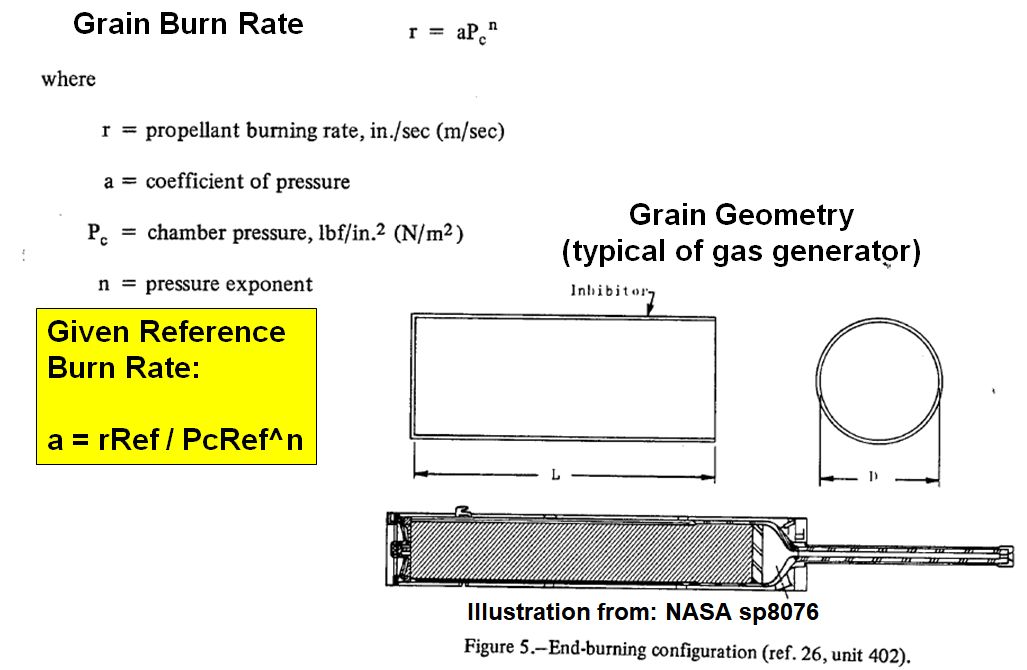

End Burning Solid Grain¶

The following script.

from prism import Grain_EndBurn

grain = Grain_EndBurn(name="grain(end burner)",

WpropBurned=200.0, propName='ARC448',

cxw=1.0, Pc=500.0, FvacMaxPerGG=300.0, IspVacDel=238.6)

print grain.getSummary()

Gives Output:

Solid Grain (End Burning): grain(end burner)

mass = 200.000 lbm

type = propellant

Propellant : ARC448

==== INPUT ====

WpropBurned = 200.000 lbm

cxw = 1

FvacMaxPerGG = 300 lbf

Pc = 500.0 psia

IspVacDel = 238.6 sec

refBurnRate = 0.1200 in/sec

refPress = 500.0 psia

BRexp = 0.6

rho = 0.0555 lbm/cuin

==== OUTPUT ====

wdotMaxPerGG = 1.25733 lbm/sec

tminBurn = 159.1 sec

BurnRate at Pc = 0.1200 in/sec

Aburn = 188.789 sqin

Dgrain = 15.504 in

Web = 19.088 in

Vgrain = 3603.604 cuin